How to Prevent Labor Errors in Agricultural Irrigation? The Role of Automation

Success in agricultural production depends on managing many variables such as soil, water, climate, and plant health in a delicate balance. However, there is a factor that disrupts this balance, which is often ignored but has a very high cost: human error. Especially labor errors made in irrigation management both directly increase costs and seriously hinder the yield to be obtained.

Imagine trying to manage a large land of 1290 decares with traditional methods (as in the example of the Süral Tarım Project). Manually opening and closing dozens of valves, operating pumps, and tracking how much each area is irrigated means a massive workload and a high margin of error. So, what exactly are these errors and how do digital agriculture technologies solve this problem fundamentally?

The Hidden Cost of Traditional Irrigation: Human Error

When we say "labor error" in agricultural irrigation, there are concrete equivalents that are directly reflected in cost and yield:

- Forgotten Valves: This is the most common error encountered in the field. Leaving a valve open longer than necessary leads to over-irrigation in that area (flooding, root rot), while causing other areas where water cannot reach to go into stress.

- Unnecessary Pump Operation: A forgotten valve means the irrigation pump operating unnecessarily for hours. This situation directly leads to an increase in energy costs of up to 30%.

- Wrong Zone or Wrong Timing: Especially wrong irrigation performed on a night with a frost risk can endanger the entire crop by making it easier for the plants to freeze.

- Inadequate Irrigation: The inability of the plant to meet its full water needs due to the worker's inability to spare time or estimation methods returns directly as yield loss.

When these errors combine, they increase water, fertilizer, energy, and labor costs, while hindering the yield you hope to obtain at the end of the season.

Solution: Technology That Eliminates Human Error – Agricultural Automation

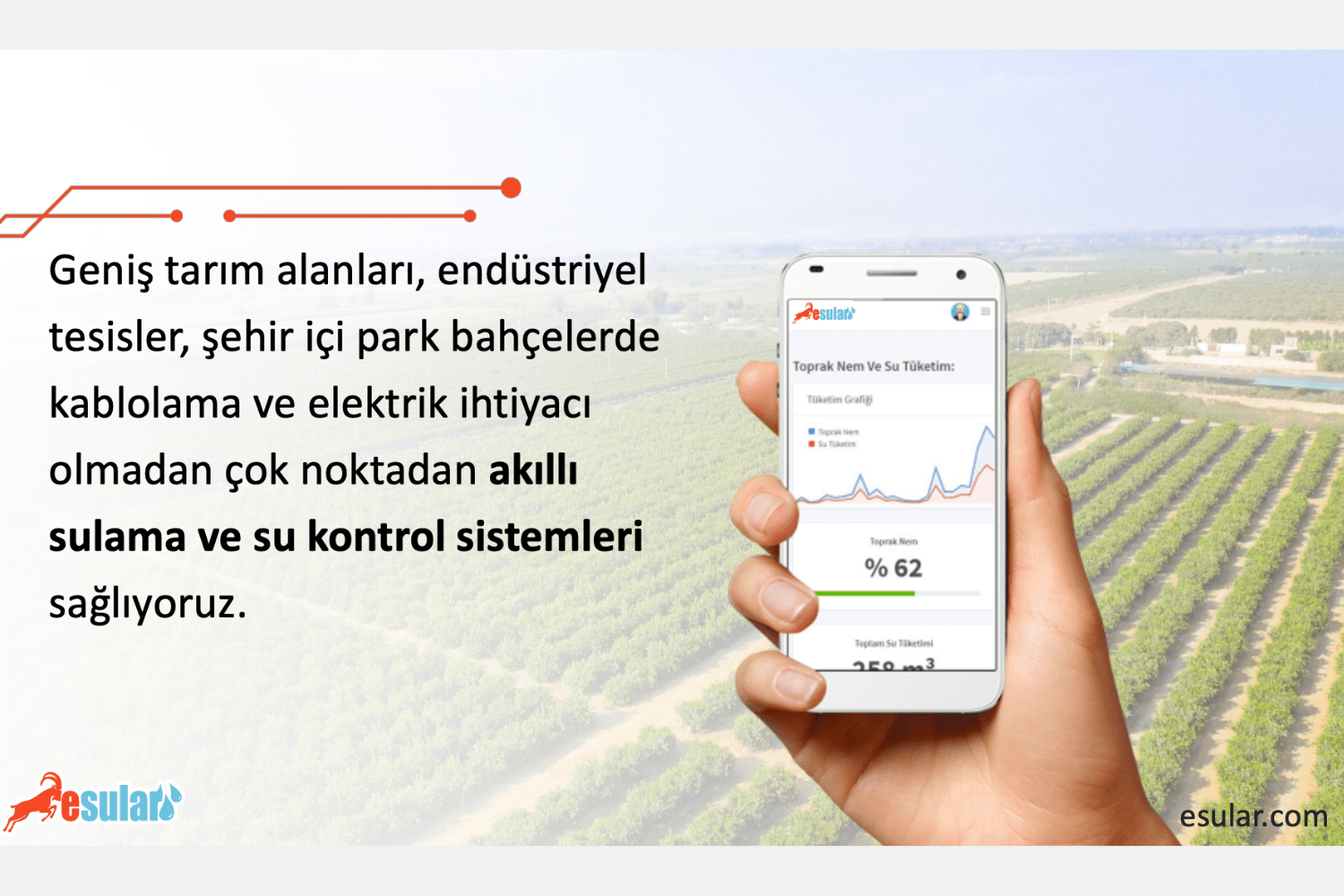

In the digital agriculture era, human error in irrigation is no longer a fate, but a choice. Esular wireless smart irrigation systems automate this entire process, taking the human factor out of the equation and leaving control entirely to data-driven algorithms.

No more concerns like "I wonder if the valve was left open?" or "Was the irrigation sufficient?". Esular's "Watch, Learn, Manage" philosophy solves exactly this problem.

How Do Esular Wireless Systems Eliminate the Need for Labor?

The system makes and implements its own decisions based on data, without the need for human intervention:

- Soil Moisture Sensors Instead of the Human Eye

Instead of a worker estimating how "wet" the soil is, it measures the moisture in the root zone of the plant instantly with centimeter precision. The system knows when the plant really needs water. - Automatic Control Instead of Manual Valve Opening

When the soil moisture falls below the determined ideal level, the system automatically sends a command to the Wireless Smart Valve Control Unit. The valve opens, and irrigation begins. - Automatic Shut-off Instead of the Risk of Forgetting

When the sensors detect that the soil has reached saturation (maximum moisture), the valve closes automatically. Not a drop of water or a second of energy is wasted. - Remote Management Instead of Going to the Field

You can monitor this entire process 24/7 from your mobile phone via the platform. If necessary, you can manually start or stop irrigation with a single button, no matter where you are in the world.

Key Products Preventing Labor Errors

The Esular ecosystem has two basic products designed specifically to prevent errors caused by labor:

1. Wireless Smart Valve Control Unit

It completely eliminates the "forgetting the valve open" problem. These solar-powered devices have a wireless range of up to 10 km and integrate into your existing valves within minutes. It keeps irrigation programs in its memory and operates automatically based on sensor data.

2. Wireless Well and Pump Control System

It solves the "unnecessary pump operation" problem. This system automatically starts the pump when valves are opened and stops it when all valves are closed. Additionally, it protects your equipment by sending you instant notifications in cases such as power outages or pressure drops.

Concrete Benefits of Automation: Costs Decrease, Yield Increases

Eliminating labor errors creates a domino effect. According to the experiences of our more than 300 customers using Esular smart automation systems, the results are clear:

- Up to 50% Water Savings: Since only as much water as the plant needs is used, waste is zeroed out.

- Up to 30% Energy Savings: Since pumps only operate as much as necessary, electricity costs decrease.

- 20-30% Yield Increase: Since the plant never experiences water stress, root development and fruit quality are maximized.

- 100% Labor Savings (Irrigation): The need to send personnel to the field for irrigation is completely eliminated.

Conclusion: Say Goodbye to Errors That Increase Costs

In traditional agriculture, labor errors were seen as an inevitable part of production and a cost item. Today, thanks to digital agriculture technologies, these errors are a preventable source of inefficiency.

Automating irrigation management with Esular not only reduces costs but also eliminates the biggest risk factor (human error) that has the potential to directly hinder yield. You can start saving water, energy, and labor today by entrusting your field to technology.

Take the First Step to Transition to Digital Agriculture

To learn how you can zero out labor errors in your land and how to transition to automation, you can request free exploration and consultancy from our expert team.

📞 Switchboard: 0850 303 49 91

📱 WhatsApp: 0541 247 45 05

✉️ E-mail: info@esular.com

🌐 Web: www.esular.com

⚠️ Prices may change. The prices of the products mentioned in this content are the list prices prior to the publication date. For current campaigns and prices, visit store.esular.com.

Yorumlar