Agricultural Pond Level Monitoring and Automation: Smart Solution in Water Management

In agricultural production, ponds are of critical importance for the storage and management of irrigation water. However, manual monitoring and control of ponds lead to both loss of time and serious water waste. At esular, the wireless pond level monitoring and automation system we have developed solves this challenge with smart technology.

Problems Encountered in Agricultural Ponds

The most common problems producers face in the management of irrigation ponds are:

Challenges in Traditional Pond Management

- Continuous Manual Control Need: Personnel need to go to the field regularly to check the pond level

- Water Overflows: Because level monitoring cannot be done, the overflowing of ponds causes thousands of liters of water to go to waste

- Insufficient Filling: Low pond levels disrupt irrigation schedules

- Energy Waste: Unnecessary operation of pumps increases electricity costs

- Difficulty of Night Control: It is almost impossible to monitor the pond status during night hours

- Multi-Point Management: It is quite difficult to monitor multiple ponds in different locations simultaneously

Each of these problems both increases operational costs and leads to the inefficient use of a precious resource like water. Especially in arid regions, water waste constitutes a serious problem not only economically but also environmentally.

esular Pond Level Monitoring and Automation System

As esular, the wireless pond automation system we have developed offers a comprehensive solution to all these problems. Our system allows you to monitor your ponds 24/7 and manage them automatically with devices that work completely wirelessly and are battery/solar powered.

System Components and Working Principle

Our pond automation system consists of smart components working in synchronization with each other:

1. Wireless Level Sensors

Our level sensors, the heart of the system, measure the water level in the pond instantly and transmit this information to the central system. We offer two different technologies:

Ultrasonic Level Sensor

- Non-contact measurement from above the pond

- 0-10 meter range

- Easy installation and maintenance

- Ideal for open ponds

- Solar panel or battery operation

Hydrostatic Level Sensor

- Pressure sensor immersed in water

- Suitable for deep ponds

- High precision

- Can be used in closed tanks

- Operation with long-lasting battery

2. Wireless Valve and Pump Control Units

According to the information coming from the level sensors, you can control pumps and valves automatically or manually. Our control unit:

- Works completely wirelessly (no need to pull cables)

- Powered by solar panel or long-lasting battery

- Communicates in a range of up to 10 km

- Has an IP68 waterproof casing

- Can control 1-3 phase pumps or electric valves

3. LoRaWAN Gateway

Acts as a bridge connecting all wireless devices in the field to the central software. With a single gateway, all sensors and control units within a 10 km radius can be managed.

4. Cloud-Based Management Platform

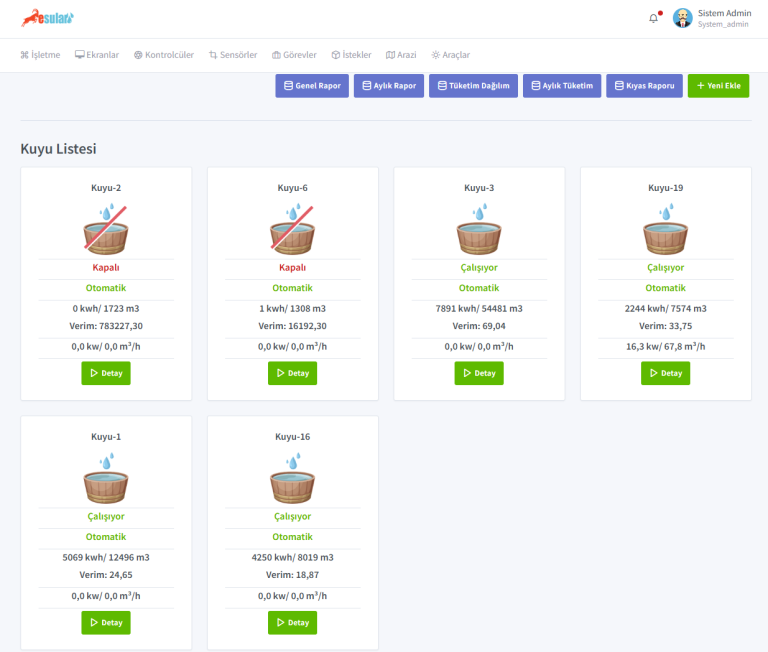

You can manage your ponds from a single center via the web and mobile application:

- Instant Monitoring: You can see the water level of all ponds in real-time

- Automatic Control: You can set scenarios such as "Open the pump when level falls below 20%, close when it reaches 90%"

- Remote Intervention: You can manually open and close pumps and valves from anywhere in the world

- Alarm System: You receive SMS or notifications during critical level changes

- Reporting: You can analyze historical data and create consumption reports

Concrete Benefits Provided by the System

The esular pond automation system offers measurable benefits to our users:

💰 Economic Gains

- 30-40% Water Savings: We minimize water waste by preventing overflows and overfilling

- 25% Energy Savings: We lower your electricity bill by preventing unnecessary pump operation

- Labor Savings: We reduce personnel costs by eliminating the need for manual control

- Fast Return: The system investment usually pays for itself within 1-2 years

⚙️ Operational Advantages

- 7/24 Monitoring: You can track the status of your ponds day and night

- Multi-Point Management: You can manage dozens of ponds from a single screen

- Easy Installation: You can commission the system in just 1-2 days without pulling cables

- Low Maintenance: Battery-powered devices operate smoothly for years

- Scalable: You can add new sensors and control points as needed

🌱 Environmental Contributions

- Sustainable Water Use: You contribute to the protection of water resources

- Carbon Footprint Reduction: You lower emissions through energy savings

- Eco-Friendly Technology: Solar-powered devices reduce fossil fuel dependency

Application Areas and Usage Scenarios

The esular pond automation system is successfully used in different agricultural applications:

Open Field Irrigation Ponds

Automation of large irrigation ponds used for field crops such as wheat, corn, and cotton. Ponds in wide areas can be easily monitored thanks to wireless technology.

Greenhouse Irrigation Tanks

Level monitoring and automatic filling of water tanks used in greenhouse enterprises. It is of critical importance for uninterrupted irrigation.

Orchard and Fruit Garden Ponds

Management of ponds feeding drip irrigation systems in fruit gardens such as citrus, apple, and cherry. Pond level control is essential for regular irrigation.

Olive and Pistachio Orchards

Automation of supplementary irrigation ponds used in dry farming products. Ideal solution for the efficient use of water resources.

Livestock Farm Water Tanks

Level monitoring and automatic filling of water tanks used in livestock facilities. Necessary to meet the uninterrupted water needs of animals.

Organized Agricultural Zones

Central management of shared irrigation ponds used by multiple producers. Important for fair water distribution and record-keeping.

Real User Experiences

Feedback we have received from producers using our system is as follows:

"We have 3 irrigation ponds in our 50-decare citrus orchard in Antalya. Before installing the esular system, the ponds were constantly overflowing and we were experiencing great water waste. Now I can see the levels of all ponds from my phone, and we achieved nearly 40% water savings with automatic filling. I no longer need to go to the field for pond filling at night."

– Mehmet B., Citrus Producer, Antalya

"I use 2 ponds in my olive orchard in Manisa. The ponds are at different points of my land and there is no electricity. Thanks to esular's solar-powered system, I can both monitor levels and control the pumps remotely. Installation was very easy, it only took 1 day."

– Ahmet Y., Olive Producer, Manisa

System Installation and Getting Started

The installation of the esular pond automation system is quite simple and fast:

Step-by-Step Installation Process

- Field Inspection: Our technical team visits the field to evaluate the number of ponds, their locations, and your existing infrastructure

- System Design: Specific sensor types, control units, and gateway locations are determined according to your needs

- Device Assembly: Sensors are mounted on ponds, and control units are mounted on pumps/valves (1-2 days)

- Gateway Installation: The central gateway is placed at a strategic point

- Software Configuration: Devices are defined in the software, and automation scenarios are set up

- Test and Commissioning: The entire system is tested and taken live

- User Training: The use of the system is explained to you or your personnel

We offer 24/7 technical support after installation. We also carry out periodic visits for regular maintenance and device checks.

Technical Specifications

Communication Technology

- LoRaWAN protocol

- 10 km range (in open area)

- Low energy consumption

- High reliability

Power Source

- Solar panel (10-30W)

- Li-ion rechargeable battery

- 5-10 year battery life (in sensors)

- Mains connection (optional)

Environmental Durability

- IP68 waterproofing

- -20°C to +60°C operating temperature

- UV resistant casing

- Dust and moisture protection

Measurement Precision

- Ultrasonic: ±1 cm

- Hydrostatic: ±0.5 cm

- 1-minute data transmission period

- Easy calibration

Related esular Products

Discover our other esular solutions that will complete your pond automation system:

- 🔹

- 🔹

- 🔹

- 🔹

Manage Your Ponds Smartly

Prevent water waste and lower your costs with the esular pond level monitoring and automation system. Contact us for discovery and technical consultancy. Request Discovery

Important Note: The product features and technical details mentioned in this blog post are for informational purposes. Please visit our store or contact us for current prices, campaigns, and stock status. All specified features may be changed without prior notice depending on technical developments.

Frequently Asked Questions

How long does the pond automation system installation take?

Depending on the number of ponds and the procedures to be performed in the field, installation is usually completed within 1-2 days. Installation is very fast as it does not require pulling cables.

Does the system work in places without electricity?

Yes, our system can operate entirely with solar panels or long-lasting batteries. It can be easily used even in locations without electrical infrastructure.

How many ponds can I manage at the same time?

You can manage an unlimited number of ponds with a single system. One gateway is sufficient for every 10 km area, and hundreds of sensors can be connected to each gateway.

Does the system require maintenance?

Our system requires minimal maintenance. Solar panels should be cleaned 1-2 times a year, and batteries should be replaced every 5-10 years. Sensor calibration should be checked once a year.

Is it compatible with my existing pumps and valves?

Yes, our system is compatible with almost all pump and valve types. 1-3 phase electric pumps, solenoid valves, and electric valves can be controlled.

Other Content You May Be Interested In:

- 📖

- 📖

- 📖

- 📖

- 📖

Yorumlar