Smart Water and Energy Management in Industrial Facilities: 30% Savings with Digital Transformation

Water and energy management in industrial facilities has become not only an environmental responsibility but also a critical element directly affecting business profitability. Thanks to wireless sensor networks, real-time monitoring systems, and artificial intelligence-supported optimization solutions offered by modern technology, factories and industrial facilities can now achieve savings of up to 40% in water consumption and 30% in energy costs.

Esular, as Turkey's leading smart water and energy management platform with over 20 years of experience, is leading the digital transformation in industrial facilities. Our system, which operates reliably at more than 300 points in 3 countries and is supported by more than 3000 connected sensors, provides end-to-end water and energy management with central software.

The Importance of Water and Energy Management in Industrial Facilities

Industrial facilities consume large amounts of water and energy in their production processes. Inefficient use of these resources both increases costs and threatens environmental sustainability. Water management in modern facilities covers these critical areas:

- Water Use in Production Processes: Cooling, cleaning, process water

- Water Requirement for Energy Production: Cooling towers, steam production

- Wastewater Management: Treatment and recovery

- Auxiliary Systems: Fire extinguishing, garden irrigation

Fundamental Problems Encountered in Industrial Facilities

1. Inefficient Well and Pump Systems

Many industrial facilities operate deep wells to use their own water resources. However, the efficiency of these wells is often uncertain. When the water level in the well is unknown, serious problems occur in the pump's operating performance. The inability to track whether the pumps are working efficiently leads to unnecessary energy consumption.

2. Loss, Leakage, and Malfunctions

Loss, leakage, and malfunctions occurring both inside and outside the well cause great water and energy waste in facilities. Since the detection of these problems is delayed in traditional systems, both financial losses increase and production interruptions occur.

3. Efficiency Losses Caused by Human Errors

Incorrect adjustments, lack of maintenance, and manual control processes lead to serious problems. The necessity for operators to be constantly in the field both increases labor costs and prevents rapid intervention.

4. Lack of Sensor and Monitoring Equipment

The lack of appropriate sensors and monitoring equipment tracking water levels in wells, pump performance, and other important data makes it difficult to detect problems quickly.

Esular Digital Water and Energy Management Solution

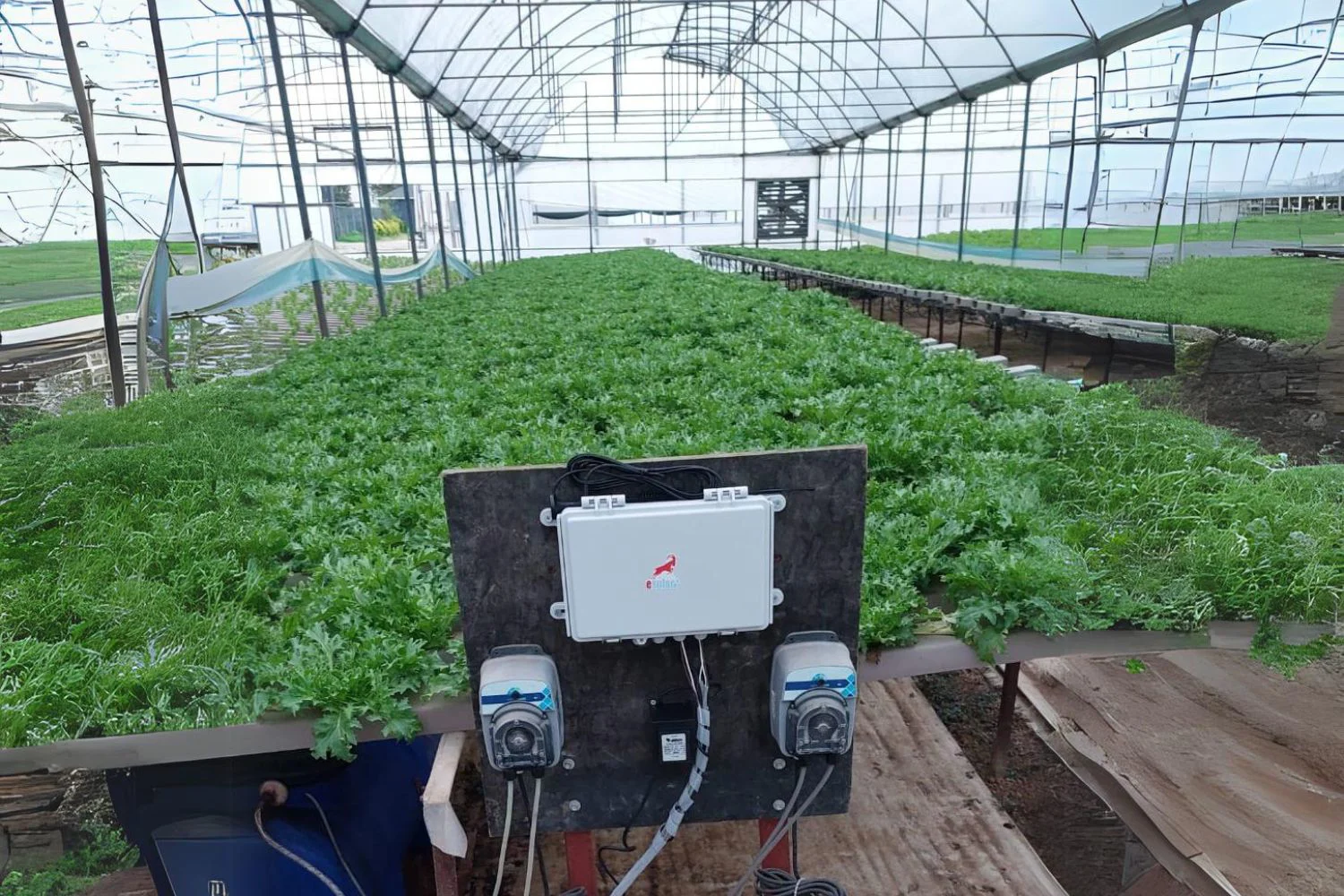

Esular offers comprehensive and technological solutions to these problems in industrial facilities. Our AI-supported system provides end-to-end water and energy management through IoT sensor networks and central software integration.

Core Components of the System

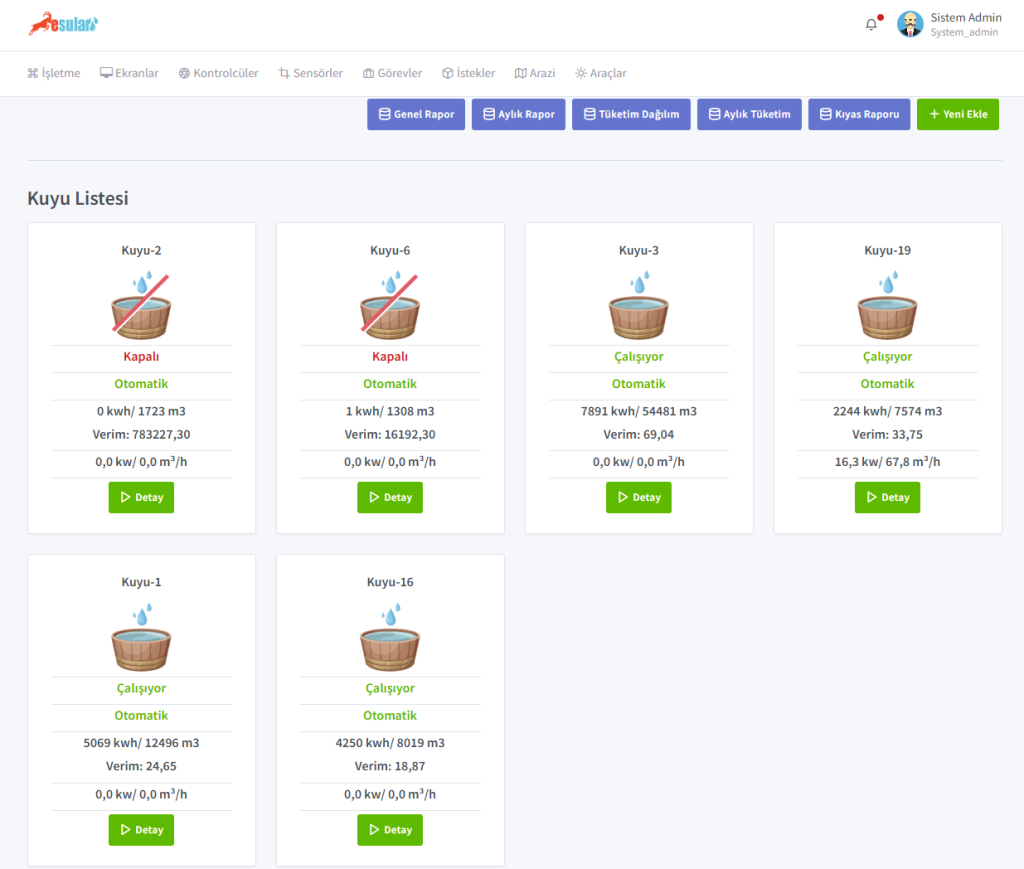

1. Well Yield Tracking and Optimization

Smart control devices are installed for each well. Well water level measurement, flow and pressure measurement, and pump energy measurement are performed continuously. Thanks to this data:

- Well efficiency status is monitored instantly

- The most efficient well is automatically selected

- The pump is kept at the optimum operating point

- Energy consumption is minimized

2. Smart Pump Control and Pressure Management

The system is equipped with high-precision pressure sensors. Pumps are operated at the maximum efficiency point through instant measurements and inverter control. In this way:

- System pressure is continuously monitored

- The pump is automatically stopped in case of excessive pressure

- The pump is automatically stopped and a notification is sent when low pressure is detected

- 15-20% energy savings are achieved

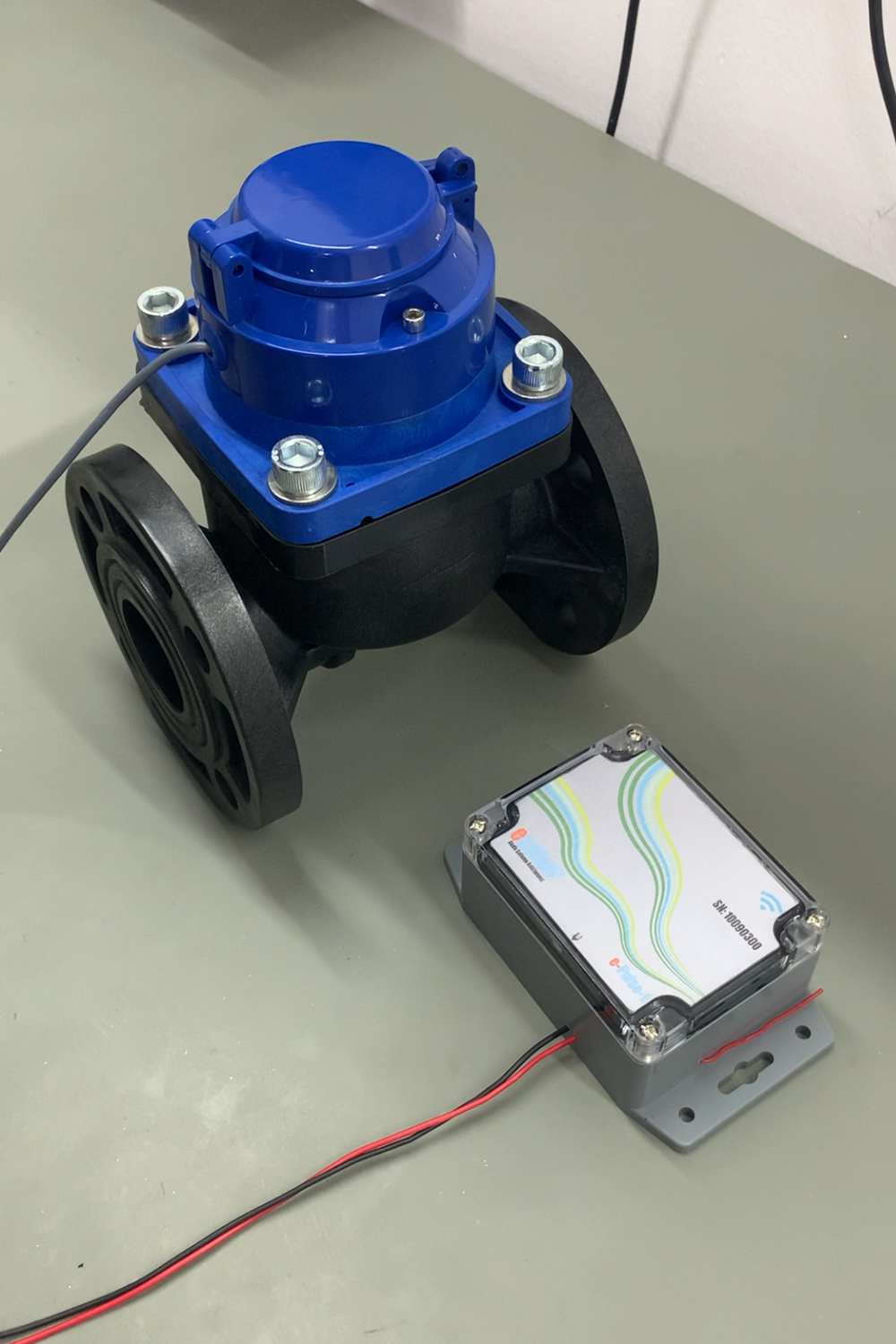

3. Water Leakage and Loss Control

Water flow is monitored instantly with a pulse-output water meter. Thanks to the control mechanism, the system minimizes loss, leakage, and malfunction situations from the start. In case of any problem, it automatically stops the system and sends an alarm to the user.

4. Smart Level Control and Tank Filling

Level sensor installation is carried out for the well and the tank. Automatic tank filling is performed by selecting the most efficient well. Water waste is prevented with dynamic tank management.

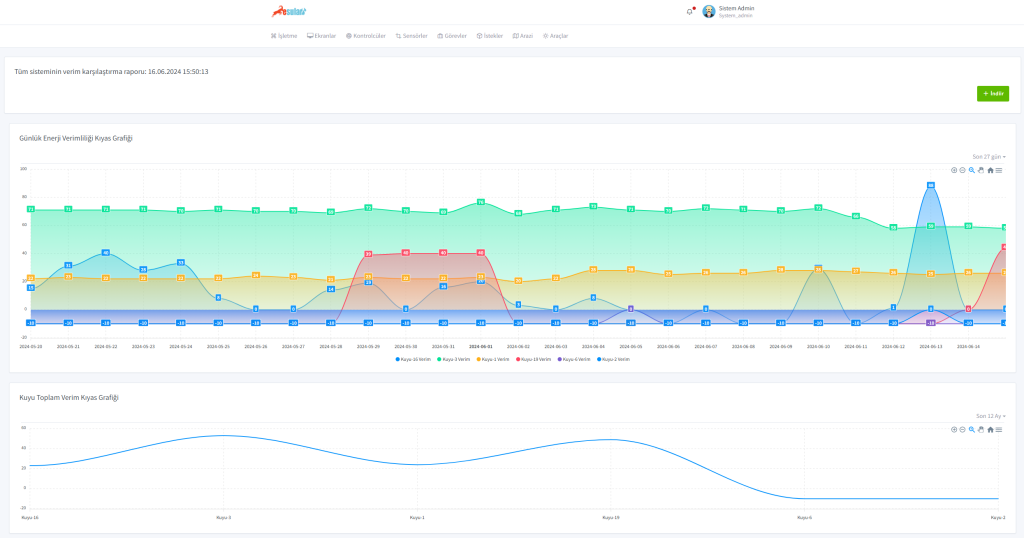

Real-World Application: Efficiency Increase and Savings Rates

The efficiency increases obtained as a result of a digitalization study carried out in an industrial facility are as follows:

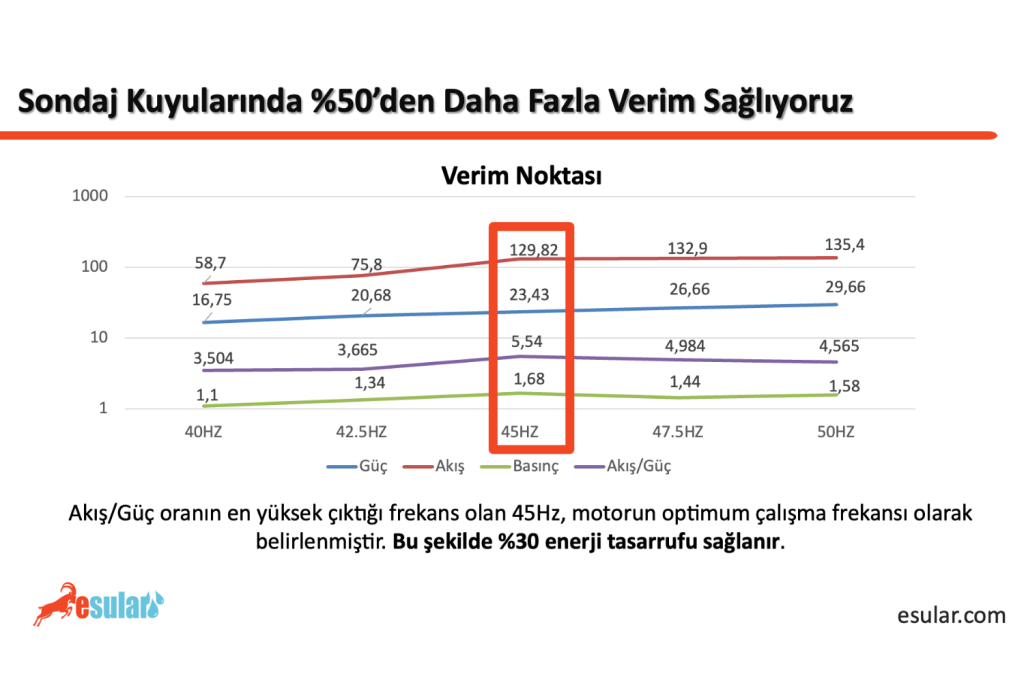

Energy Optimization and Savings

By conducting a pump efficiency point analysis, the frequency where the flow/power ratio is highest is determined. An example analysis result:

The 45Hz frequency, where the flow/power ratio is highest, is determined as the motor's optimum operating frequency. With this optimization, 30% energy savings are achieved.

Proven Savings Rates

- 30% Energy Savings: Efficient well management and pump optimization

- 40% Water Savings: Loss-leakage prevention and smart level control

- 60% Labor Savings: Automatic control and remote management

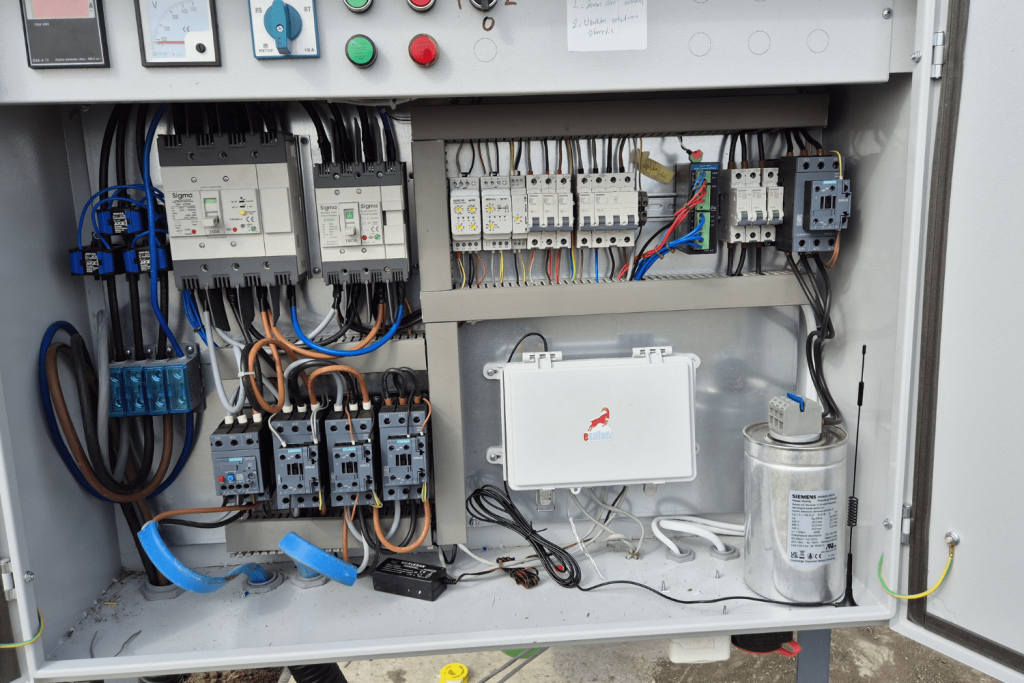

Wireless IoT Technology and Central Software

One of the biggest advantages of the Esular system is that it uses a completely wireless IoT infrastructure. In this way:

- Does not require complex wiring, installation is fast and easy

- Integrated into existing facilities with minimum intervention

- Data transmission in 10+ km range with LoRaWAN technology

- Access from anywhere with GSM/4G connection

- Solar panel support for energy independence

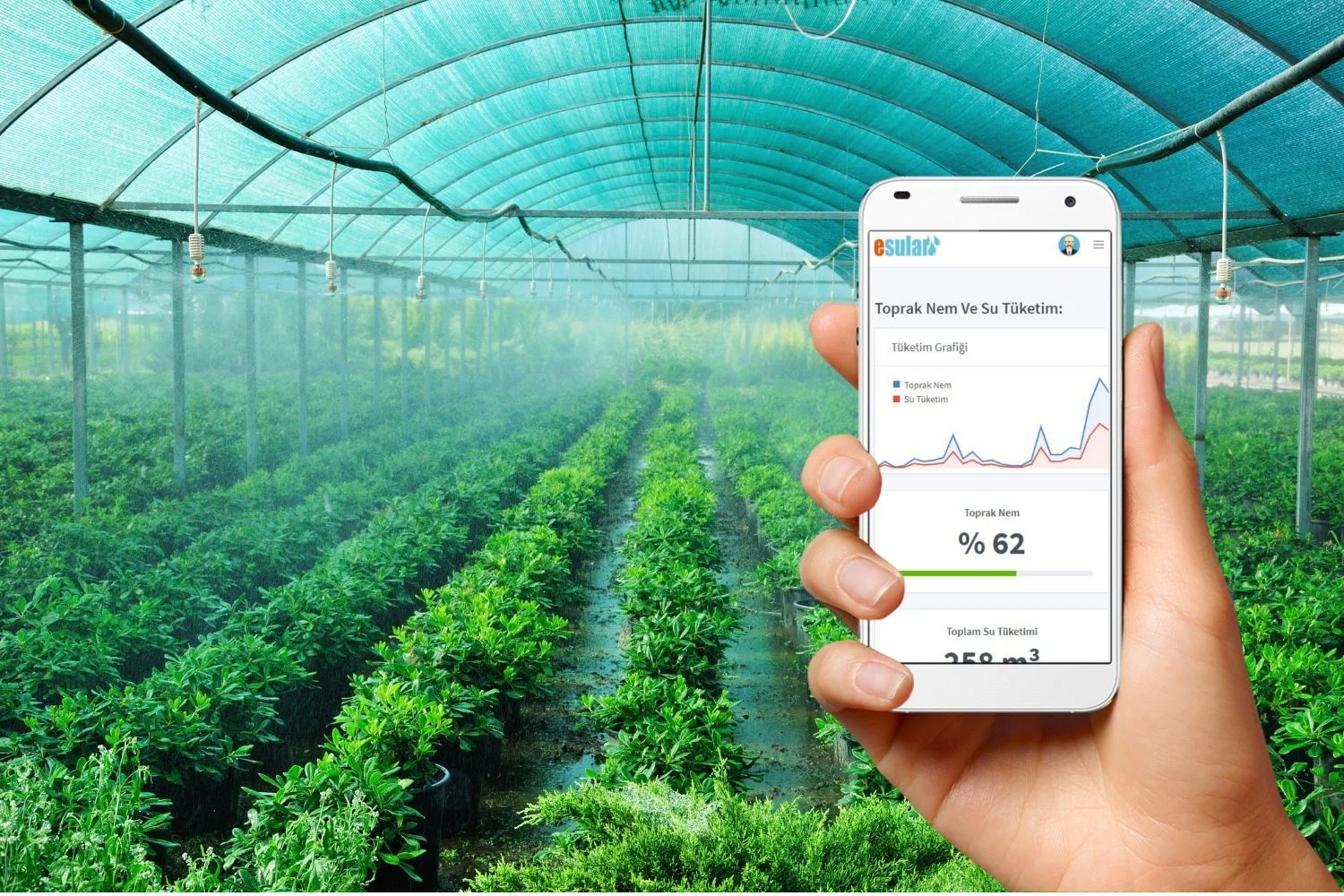

Real-Time Monitoring and Control

Thanks to the central software platform, all system parameters are monitored in real-time:

- Well water levels and pump statuses

- Energy consumption and cost analysis

- Water consumption and flow graphs

- Pressure and flow rate values

- Alarm and malfunction notifications

- Efficiency reports and trends

Visualization of the Entire System via Map

Esular's unique map-based interface offers the possibility to visually manage the water and energy infrastructure throughout the facility:

- Geographical locations of all wells

- Active and passive pump statuses

- Active zones of irrigation systems

- Instant status indicators

Comprehensive Solution Package for Industrial Facilities

Esular provides services to industrial facilities in the following scope:

- Wireless Multi-Point IoT Management: Central control of all water points throughout the facility

- Smart Water Management: Real-time consumption tracking and optimization

- Sensor-Supported Energy Optimization: Pump and motor efficiency analysis

- Loss-Leakage Tracking with Water Meters: Instant leakage detection system

- Industrial Tank Filling: Automatic and efficient water transfer

- Various Environmental Monitoring Sensors: Temperature, humidity, pressure, level

- Software and Application Support: Full control via mobile and web

- Integration: Compatibility with existing SCADA and ERP systems

- Additional Sensor Solutions: Expandable infrastructure specific to needs

System Installation Process

The Esular industrial facility digitalization process consists of the following steps:

1. Situation Analysis and Planning

The facility's current water and energy infrastructure is examined, and a needs analysis is performed. Consumption points, pump stations, wells, and distribution lines are mapped.

2. System Design

A customized sensor network, control units, and software integration are designed. Compatibility with existing systems is ensured.

3. Installation and Commissioning

Wireless IoT devices, sensors, and control units are installed. System tests are performed and user training is provided.

4. Monitoring and Optimization

The system is continuously monitored, efficiency analyses are performed, and improvement suggestions are presented. Remote support and maintenance services are provided.

Return on Investment Calculation

Investment analysis for an average industrial facility:

Current Situation:

- 7 well pumps (15 kW each)

- Total monthly energy consumption: ~25,000 kWh

- Average electricity cost: 3 TL/kWh

- Monthly electricity bill: 75,000 TL

- Water loss and waste: 20%

With the Esular System:

- Energy savings (30%): 22,500 TL/month

- Water savings (40%): 15,000 TL/month

- Labor savings (60%): 10,000 TL/month

- Total monthly savings: 47,500 TL

- Annual savings: 570,000 TL

Average system installation cost: 250,000 – 400,000 TL

Return on investment period: 6-8 months

Esular Product Ecosystem

All products necessary for industrial facility management: https://store.esular.com/store/ProductEmbed?slug=kablosuz-kuyu-ve-pompa-kontrol-sistemi-gsmli-f-serisi-0 https://store.esular.com/store/ProductEmbed?slug=kablosuz-sulama-kontrol-cihazi-akilli-vana-unitesi-0 https://store.esular.com/store/ProductEmbed?slug=kablosuz-pilli-toprak-nem-sensoru-0

Sustainability and Environmental Impact

Esular systems not only provide cost savings but also make a great contribution to environmental sustainability:

- Carbon Footprint Reduction: ~180 tons of CO2 emission reduction annually with energy savings

- Protection of Water Resources: Preservation of natural resources with 40% water savings

- Efficient Resource Use: Optimum pump operation and smart distribution

- Waste Reduction: Extension of pump life and reduction of maintenance costs

Conclusion: Prepare for the Future with Digital Transformation

Digitization of water and energy management in industrial facilities is no longer a luxury but a necessity. Rising energy costs, water scarcity, and environmental regulations are forcing facilities to operate more efficiently. With Esular's wireless IoT technology, AI-supported optimization, and central management platform:

- You achieve energy and water savings of 30-50%

- You detect malfunctions in advance with real-time monitoring

- You reduce operating costs with remote control

- You perform continuous improvement with data analytics

- You reach your environmental sustainability goals

With over 20 years of experience, 300+ successful projects, and an ecosystem supported by 3000+ active sensors, Esular is ready to carry your industrial facility into the future.

Are You Ready for Digital Transformation in Your Facility?

Achieve 30% energy and 40% water savings with Esular smart water and energy management systems. Discover the solution specific to your facility by speaking with our expert team.Examine ProductsContact Us

Price Warning: The product prices and savings calculations mentioned in this article were made according to the list prices valid as of the date the content was published. For current prices, campaigns, and special offers, please visit the product pages or contact us. Energy costs and savings rates may vary according to usage conditions.

Yorumlar