Drilling Wells

Drilling is the process of opening a hole in the ground, carried out with the necessary drilling machines to obtain natural resources such as water, oil, and natural gas from underground and make them available for use. In drilling machines used to open holes vertically in the ground, a deep drilling process is performed with a sharp tool such as a drill bit. At the same time, in some types of drilling, it is necessary not to drill directly into the underground reserves. In such cases, this process is carried out with angled drilling called horizontal drilling. When the reserves are reached by excavation, the drilling work is completed, and the drilling work is finalized by bringing it to the surface with the help of pipes and integrating the necessary equipment (pipes, valves, etc.) into the system.

What is Water Drilling?

Water drilling is one of the most used methods in drilling to reach the water level deep in the soil. It ensures the use of natural spring waters located underground and water puddles formed by natural filtering through stones after accumulating with rain. If the water deep in the soil is pressurized water, an artesian well is opened after this drilling process; however, if it is not pressurized, a channel is opened with the help of a PVC pipe to send a submersible pump underground while performing the drilling process in the area where the well is opened. The amount of water to be used is determined by making the necessary measurements. Then, an appropriate submersible pump is lowered to the bottom of the well, and the water from the underground well is made available by pumping water upwards.

What is Water Drilling Done For?

The main purpose of water drilling is to reach the water at a certain depth underground in the region or land to be worked on and to bring the water to the surface by drawing it with a pump.

What are the Water Drilling Methods?

There are different drilling methods for wells, such as rotating pipes of a certain diameter and depth from the surface inwards with the help of a drill bit, or using a percussion wire, rope, and drill bit. According to the application method, drilling types are divided into three; these are:

- Rotary Mud (Circulation) Water Drilling: The cylindrical excavation process performed by rotary drillers that rotate around their own axis and cut, break, or grind the structure they rotate on is called "rotary drilling."

- Percussion Air (with Compressor) Water Drilling: The drilling process where a heavy cutter with a sharp edge is released onto the formation with ropes or rigid rods, and the cuttings resulting from the excavation process performed towards the depth are taken up with tools such as buckets, etc., is called "percussion drilling."

- Combined (Mud-Air) Water Drilling: This drilling method emerged by combining the two drilling methods above. This method is used when underground changes occur.

Performance Monitoring in Drilling Wells

In well drilling, there may be curved drillings; although the ideal is a well that has not deviated from the vertical, in practice, there is some deviation in every well, and despite the use of a filtration system, foreign matter accumulation is seen in the well over time. Therefore, fillings occur in the well over time, the pump wears out, yield decreases, and efficiency cannot be obtained. To prevent the decrease in yield:

- Hydrographic and hydrogeological data (dynamic-static water levels, approximate flow measurement, etc., data that needs to be calculated) belonging to the well to be opened should be calculated and interpreted correctly.

- Pump depth, pump type, and other pump characteristics should be correctly followed in the performance of the well.

- In the wet drilling system, the drilling must be cleaned after the drilling well is opened. Flow measurement should be performed during this cleaning.

- Knowing the water level is very important for the correct placement of the casing pipes.

It is necessary to pay attention to the items above.

What Do We Do as Esular for Performance Monitoring in Drilling Wells?

Due to the reasons mentioned above, performance monitoring should always be carried out in a drilling well. Thanks to the solutions we offer as Esular, you can automate your active water yield performance monitoring.

Our Solutions;

Wireless Battery-Powered Pressure Sensor

Pressure measurements are made at certain intervals and transmitted to our server, and pressure values can be monitored from here. At the same time, these values are transmitted to the server as soon as certain intervals are exceeded, and alarms can be created. Limit values can be adjusted remotely and wirelessly.

In this way, we ensure efficiency.

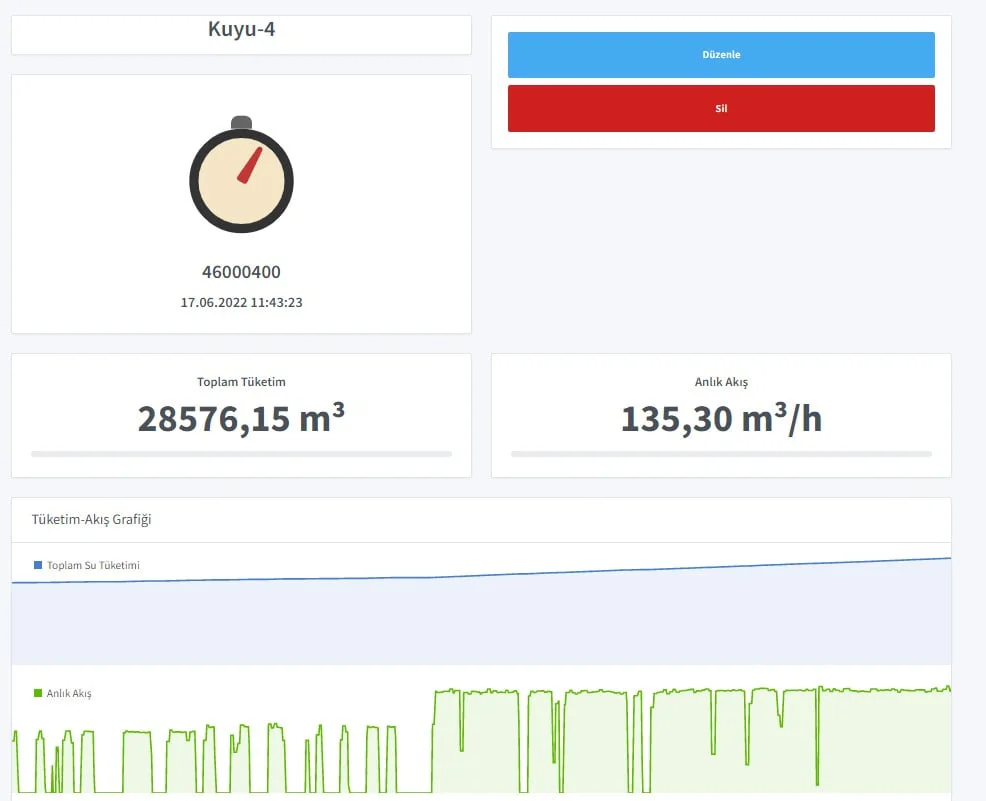

Wireless Battery-Powered Meter Flow and Consumption Sensor

Thanks to the wireless battery-powered meter flow and consumption sensor, moisture measurements are made at certain intervals and transmitted, and meter flow and consumption values can be monitored remotely.

It works wirelessly. Measurement values are transmitted to the server at certain intervals. At the same time, these values are transmitted to the server as soon as certain intervals are exceeded, and alarms can be created. Limit values can be adjusted remotely and wirelessly.

Wireless Battery-Powered Ultrasonic and Graduated Level Sensor

We can provide wireless control in well filling and water level monitoring processes with the wireless battery-powered float status control sensor transmitter and receiver.

Since we work with batteries, we offer suitable solutions especially for the use of drilling wells in regions where there is no energy.

When the water level reaches the desired height, it transmits the status information to the receiver, allowing you to control your pressure, flow, etc. systems.

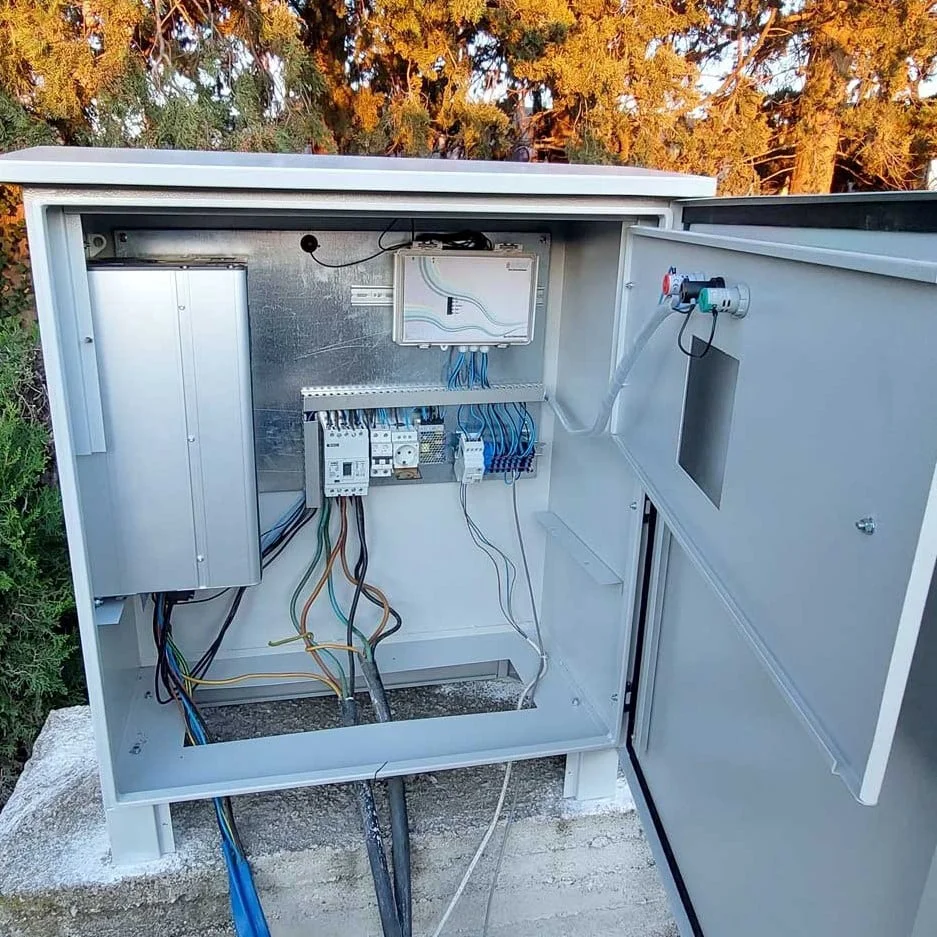

Active Pump Control with Inverter

Since the pumps used in wells are sensitive devices, we ensure the protection of the pump and increase its efficiency with the help of an inverter.

We ensure the use of electricity gradually. Or if there is an invisible problem with the electrical installation, they are detected and transmitted to the server. We provide warnings, alarms, and notifications in cases such as leakage; notifications via SMS and e-mail.

Practical Use with Web and Mobile Application

We include the sensors we use in the performance monitoring system into the practical and easy-to-use web and mobile application; we provide warnings, alarms, and notifications; notifications via SMS and e-mail.

All values can be controlled remotely.

You can use our smart sensor solutions to increase the active efficiency and performance of water. To get more detailed information;

You can visit our address.

Yorumlar