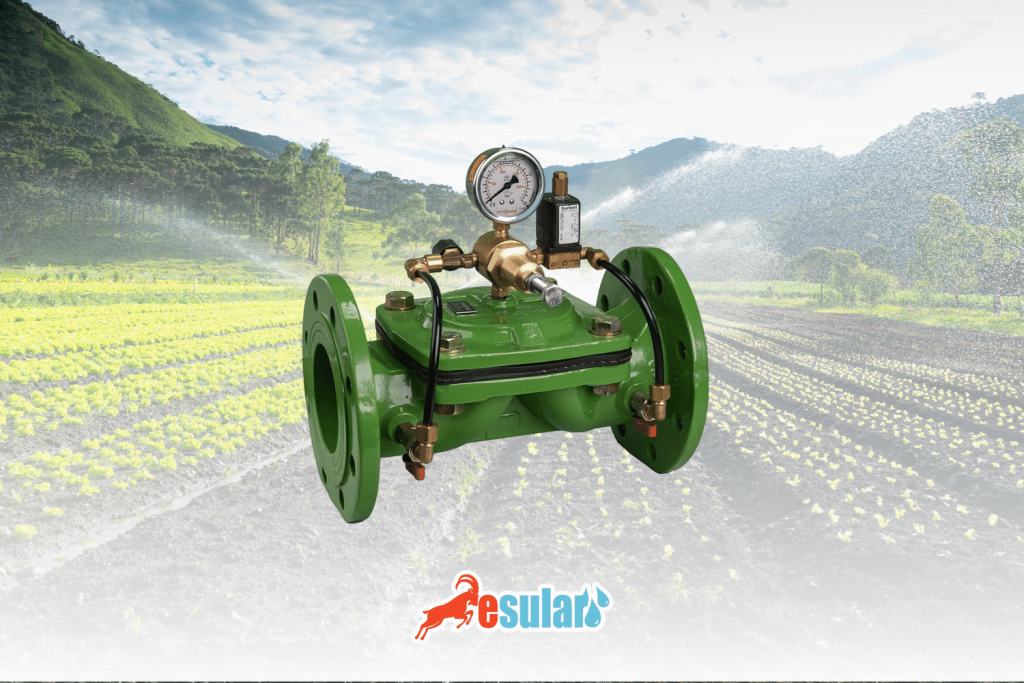

Automatic Irrigation Valves-Solenoid Valve

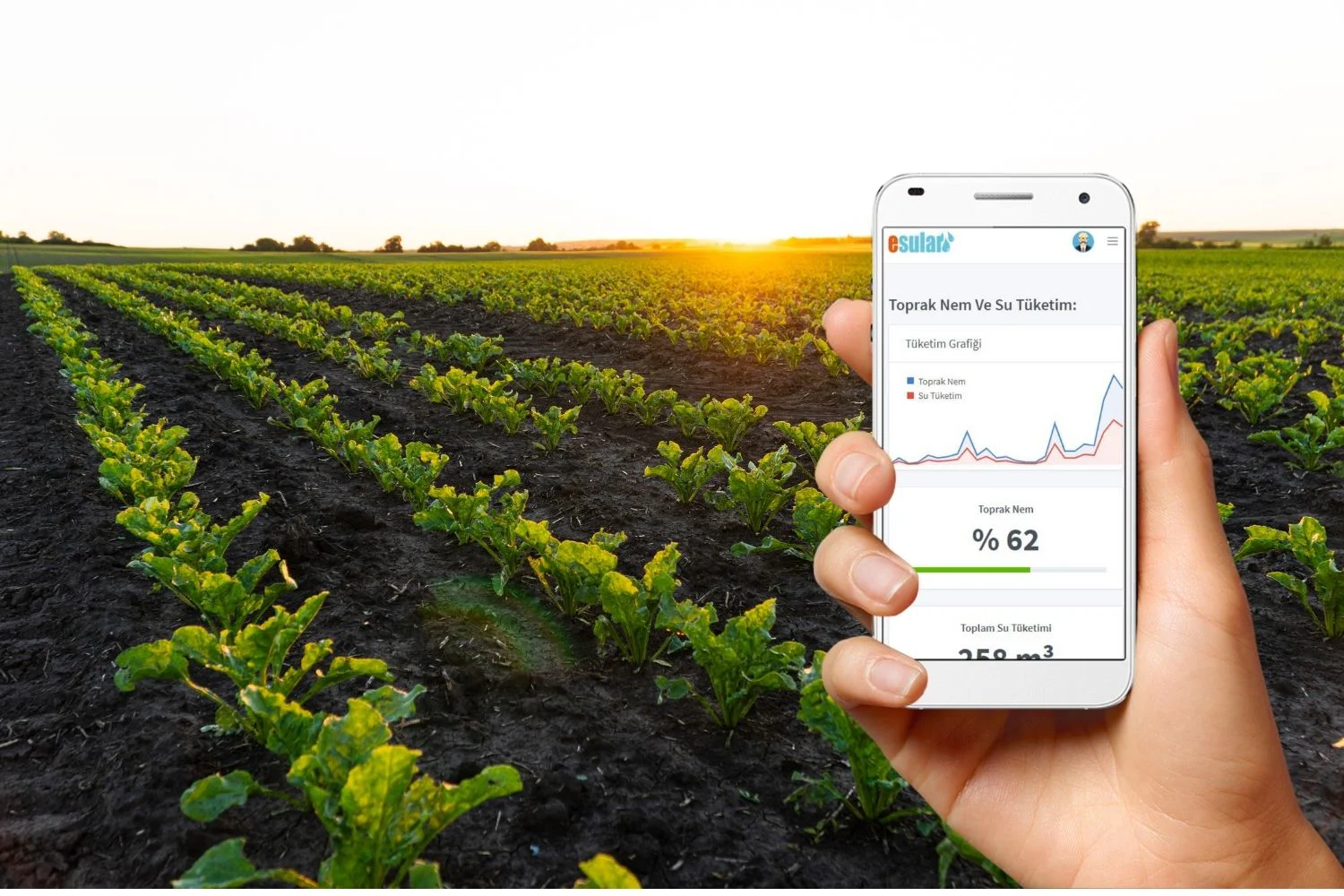

Automatic irrigation valves optimize irrigation processes and provide water at desired times and amounts without the need for human intervention. Operating with electrical signals, these valves control water flow quickly and reliably. The precise control offered by solenoid valves provides high sensitivity by opening and closing the water flow within milliseconds. It offers reliable performance with its robust and long-lasting structure. Solenoid valves, which can adapt to different pressure ranges, support optimal growth conditions for plants while ensuring the effective use of water resources. When used together with automatic irrigation valves, they optimize irrigation processes, preventing water waste and creating ideal conditions for plant development. These technologies are indispensable tools for those seeking sustainable and efficient irrigation solutions in the field of agriculture and landscaping.

Where is a Solenoid Valve Used?

- Agricultural, Park Garden, Landscape, Irrigation Systems: Solenoid valves are used to control the flow of water in drip irrigation systems, sprinkler systems, and similar irrigation systems, for irrigation automation and remote control.

- Fertilizer Injection: In agricultural applications, when fertilizers or chemicals need to be injected into plants, solenoid valves perform this process automatically.

- Greenhouse Control: Solenoid valves can be used to control temperature, humidity, and other environmental factors in greenhouses. This ensures that plants have the best growth conditions.

- Water and Wastewater Processing: Control of water flow in irrigation systems and wastewater treatment plants is done with solenoid valves.

- Industrial pool filling: It fills the water level in pools at the desired level with the support of sensors used.

- Animal Watering: Solenoid valves can be used in animal watering systems. These systems provide water automatically to meet the water needs of animals.

- Feed Distribution: Solenoid valves can help distribute feed in correct amounts and on time in feed distribution systems.

How Does a Solenoid Valve Work?

Solenoid valves are electromechanical devices that control the flow of fluids (liquid or gas) by converting electrical energy into mechanical energy. These valves start working when they receive an electrical signal. The electrical signal is transmitted to the solenoid coil, and this coil acts as an electromagnet, creating a magnetic field. The resulting magnetic field moves the metal core (plunger) inside the valve. The movement of the core changes the position of the orifice (hole) inside the valve. When the core moves up, the orifice opens and allows fluid passage; when the core moves down, the orifice closes and prevents fluid passage.

In normally closed (NC) valves, the valve remains in the closed position when the electrical energy is cut off. When energy is applied, the magnetic force pulls the core up, and the orifice opens, allowing fluid passage. In normally open (NO) valves, the valve remains in the open position when the electrical energy is cut off. When energy is applied, the magnetic force pushes the core down, and the orifice closes, preventing fluid passage. In pilot-controlled solenoid valves, the solenoid coil controls the pilot valve rather than the main valve mechanism directly. The pilot valve changes the pressure on the main valve, causing the main valve to open and close. When the electricity is cut off, the coil loses its energy and the magnetic field disappears. In the absence of a magnetic field, the spring inside the valve pushes the core back to the original position of the orifice. In this way, normally closed valves close and normally open valves open.

Solenoid valves regulate the flow of fluids by operating with electrical signals. The electric current applied to the coil creates a magnetic force, and this force moves the core inside the valve. This movement ensures the opening or closing of the valve, thus controlling the passage of the fluid. When the electricity is cut off, the valve returns to its original position, providing reliable and automatic control.

Solenoids Used in Agricultural Areas and Landscape Areas

9V Latching Solenoid Valve

A 9V latching solenoid valve is a type of solenoid valve and usually operates with a 9 Volt electrical source. The general features of 9V latching solenoid valves are as follows:

- They are generally characterized by low power consumption, therefore they are widely used in battery-based or portable applications.

- Available in diameters of 3⁄4” 1” 11⁄2” 2” 21⁄2” 3’’ 4’’.

- It opens and closes at 9V DC voltage and maintains its position when energy is cut off.

- It has various mounting options. Different installation options such as threaded or flanged, horizontal or vertical mounting can be offered.

- It opens and closes at 9V DC voltage and maintains its position when energy is cut off.

- There can be a current consumption between 10 mA and 200 mA.

- Operating frequency is usually 5 Hz to 20 Hz.

- 9V latch solenoid valve has cable connections in 2 different colors.

- It has a maximum operating range of 10 bar.

Cast Solenoid Valve

Cast solenoid valves are used after high diameters. General features of cast solenoid valves:

- Used in diameters of 5″ 6″ 8″ 10″.

Compatible with 9-12V DC Latch and 24V AC coils. - Resistant to high pressure values.

- Has a range of 10/16 bar.

- Has various mounting options.

- Different installation options such as threaded or flanged, horizontal or vertical mounting can be offered.

- For a 24V solenoid valve, current consumption can be between 100 mA and 500 mA, and for a 9-12V DC Latch solenoid valve, it can be between 10 mA and 200 mA.

- 24 Volt AC 50 Hz or 60 Hz with 12 Volt DC, 9 Volt DC latch and 12 Volt DC latch normally open (N.O) or normally closed (N.C.) solenoid coils can be used.

Pressure Controlled Solenoid Valve

A pressure controlled solenoid valve is a type of solenoid valve that can sense pressure values and control the opening and closing of a solenoid valve according to these values. General features of pressure controlled solenoid valves:

- They operate with a low-voltage power source.

- Available in diameters of 3⁄4” 1” 11⁄2” 2” 21⁄2” 3’’ 4’’ 5’’ 6’’.

- Low energy consumption

- Compatible with 9-12V DC Latch and 24V AC coils.

- Reduces the inlet pressure value to the desired pressure value.

- Solenoid valve electrical signal is equipped with a control device, time relay, switch, PLC control unit and control equipment.

- Automation and control can be easily achieved in application systems.

- Has various mounting options. Different installation options such as threaded or flanged, horizontal or vertical mounting can be offered.

- For a 24V solenoid valve, current consumption can be between 100 mA and 500 mA, and for a 9-12V DC Latch solenoid valve, it can be between 10 mA and 200 mA.

Angled Solenoid Valve

Angled solenoid valves are a type of solenoid valve and are compatible with 9-12V DC Latch and 24V AC coils. It offers ease of use thanks to its angled structure. General features of angled solenoid valves:

- Available in diameters of 3⁄4” 1” 11⁄2” 2” 21⁄2” 3’’ 4’’.

- Compatible with 9-12V DC Latch and 24V AC coils.

- Has an angled body structure.

- Different installation options such as threaded or flanged, horizontal or vertical mounting can be offered.

- For a 24V solenoid valve, current consumption can be between 100 mA and 500 mA, and for a 9-12V DC Latch solenoid valve, it can be between 10 mA and 200 mA.

- There can be a current consumption between 10 mA and 200 mA.

- 24 Volt AC 50 Hz or 60 Hz with 12 Volt DC, 9 Volt DC latch and 12

- Volt DC latch normally open (N.O) or normally closed (N.C.) solenoid coils can be used.

- It has a maximum operating range of 10 bar.

To get more detailed information about automatic irrigation valves, you can reach us through our contact number.

Yorumlar